Clients First Approach

Don't Get Lost in ERP Selection Chaos: Now is the moment to seize command of your business's future. Join forces with Clients First to harmonize your people, processes, and systems. Don't let this chance slip awaytrailing behind!—ignite growth, optimize operations, and leave your competitors

Industry

Invest in sophisticated technology that meets your Print, Manufacturing, Distribution, or MRO business needs of today and grows with your organization tomorrow.

Learn More

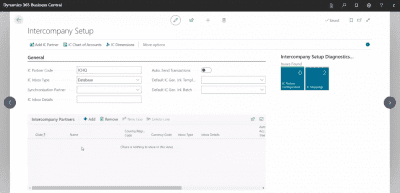

Solutions

Manage your operations, realize your goals, and proactively grow with tailored and scalable ERP, infrastructure, reporting, and security technology.

Learn More